Sustainable production and technologies

Not all major environmental problems can be solved with big, individual ideas. If we want to make our economy more environmentally friendly, we need to re-think our production processes and technologies and find a myriad of new solutions – in completely different fields.

This research field therefore covers many different aspects, which fit together like puzzle pieces, with the aim of making our economy and industry more environmentally friendly as a whole. In many fields, research is highly application-driven: it is not about big visions for a distant future but about the development of innovative technologies and processes which can then be used directly by industry.

Biotechnology: chemistry goes green

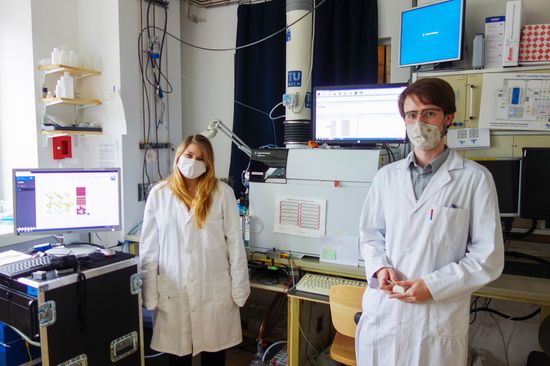

For example, chemical processes in bioreactors are carefully analysed so that the desired chemical products can be produced using biological processes. Many synthetic chemical processes also produce by-products that are damaging to the environment – research groups working on “green chemistry” develop new synthetic processes which are better for the environment. Toxic solvents, for example, have been replaced with hot water in the manufacture of certain high-performance plastics.

The question of how to best use raw biomaterials and which products can be made from improved biomaterials requires a lot of chemical expertise – something which is under continuous development at TU Wien. One field that will gain in economic importance in the not-too-distant future is the biorefinery: biogenic (waste) materials can be recycled using a clever process, thereby helping to reduce our CO2 emissions significantly.

CO2 reduction is generally the aim of many of the other technologies that TU Wien is working on, from engines to combined heat and power stations. This field also includes applications that you might not immediately associate with CO2 emissions – such as ultrasound or laser technology for innovative sensors that can be used for environmental applications.

Sustainable materials

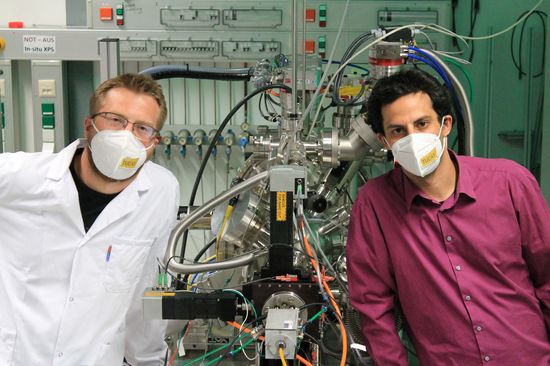

New forward-looking materials, from special concrete to innovative semi-conductor structures for better photovoltaics, are being developed in conjunction with research groups from other materials research disciplines. The properties of existing materials are being improved – at incredibly different scales, from huge construction elements down to the molecular level. Materials are simulated on the computer, produced, tested and used.

Re-thinking production processes

To make industry more environmentally-friendly, however, we need to optimise not only the material, but the production processes themselves. Huge increases in efficiency can often be achieved through precision analysis and optimisation of industrial processes.

Modern IT solutions can be used to proactively control large-scale systems while modern machine technology can be used to lower resource consumption and energy needs. This often requires highly complex simulations and sophisticated computer tools which are developed at TU Wien. Our experts are therefore working across disciplines in the fields of modelling, control, regulation and automation with the latest computer, information and communication technology.

Stadt- und Raumentwicklung der Zukunft

- Regionalentwicklung

- Siedlungs- und Bebauungsstrukturen

- Stadtverkehr und kommunale Mobilität

- Stadtraumsimulation

- ökonomische Gesamtbetrachtungen

Energie- und ressourceneffiziente Bauwerke (Aktiv-/Passivhaus)

- Ökoeffizientes Bauen

- Einsatz erneuerbarer Energieträger

- Gebäudekonzepte und Ressourcenoptimierung (Gebäudehülle, Gebäudetechnik, etc.)

- Simulation und Optimierung Gesamtsystem

Intelligente Gebäude und Siedlungen

- Gebäudemonitoring

- Smarte und Verteilte Systeme

- Gebäudeautomation und Integration

- Energiemanagement (microgrid, smart meter)

Innovative Immobilienbewirtschaftung und Infrastruktur

- Gebäudebestand (Bestandsaufnahme, Sanierung)

- Integrale energieeffiziente Planung

- Lebenszyklusanalysen

- Gebäude- und Immobilienbewertung

Soziologische und Ökologische Aspekte

- Nutzer- und Verbrauchsverhalten

- Mikroklima und Raumkomfort

- innovative und ökologische Baustoffe

- Auswirkungen Klimawandel, Makroklima

Resource-efficient production

- Production and process management and optimisation

- Machine technology and optimisation

- Modelling, control, regulation and automation

Bioprocesses and green chemistry

- Biological methods

- Bioproducts and biomaterials

- Use of raw biomaterials

- Green chemistry

Innovative new technologies and processes

- Biorefineries with optimised material and energy usage

- CO2-reducing technologies and applications

- Development of ultrasound and laser technology and sensors

Sustainable materials and their applications

- Optimisation of material properties

- Future-oriented materials

- Sustainable material development and material test processes

Im Forschungsschwerpunkt Energie und Umwelt sind alle acht Fakultäten der TU Wien vertreten, rund zwei Drittel der Institute. Mehr als 80 Forschungsgruppen forschen gezielt in unterschiedlichsten Aspekten zum Thema Energie und Umwelt.

Das im selben Zeitraum eingeworbene Drittmittelvolumen für den Forschungsschwerpunkt Energie und Umwelt beträgt rund 56 Mio. €.

Der Forschungsoutput in den einzelnen Forschungsfeldern ist unterschiedlich - von den verschiedenen Messzahlen zur Quantifizierung der Forschungsaktivitäten wurden das projekt-finanzierte Personal (Abb. 1) und die Anzahl der publizierten Zeitschriftenbeiträge (Abb. 2) ausgewählt.

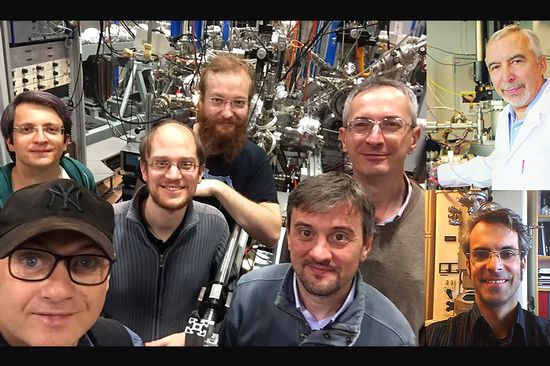

Four faculties are active in this field of research in particular – Technical Chemistry and Electrical Engineering and Information Technology account for around two thirds of the project volume. The other two are the faculties of Mechanical and Industrial Engineering and Civil Engineering.

Research groups from 31 institutes are carrying out research into more resource-efficient production as well as innovative technologies and processes. Around 4.8 million euros is invested in around 90 projects per year. There has been a significant rise in the academic output in recent years – this can be seen in the SCI publications in particular.

All data and information provided relates to the research period 2016-2018 (based on the period of the Performance Agreement).

The hidden talent of fungi

Water replaces toxins: Green production of plastics