(Presse Release) TU Wien will present work on the topic of helicopter safety as part of the EASA-Rotorcraft Symposium as well as at the European Rotors Exhibition from the 16th to the 18th of November in Cologne, Germany.

© Background: 2021 American Chemical Society

Neuartige konventionelle Schmierung sowie innovative 2D-Materialien

© TU Wien - IKP

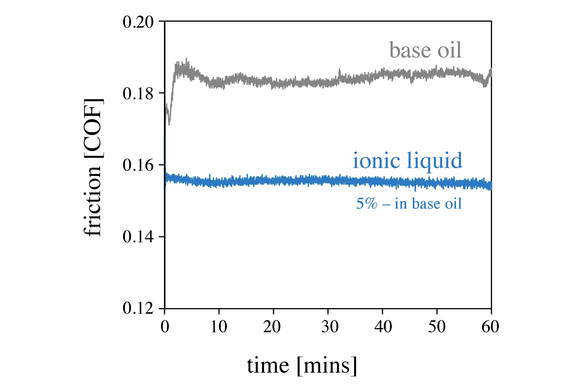

Substential reduction of friction by use of ionic liquid

© TU Wien – IKP

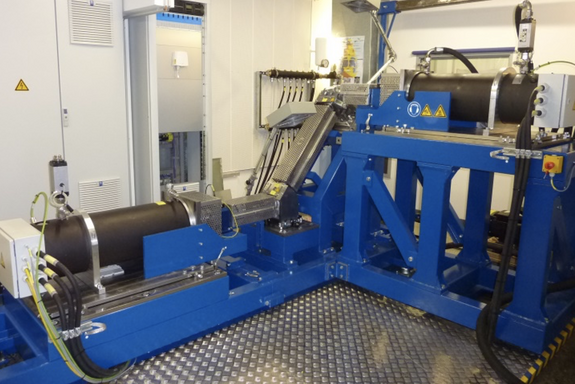

Unique universal test stand for helicopter drive trains at TU Wien

Prof. Dr.-Ing. Carsten Gachot, TU Wien – Research Unit Tribology

Prof. Dr.-Ing. Michael Weigand, TU Wien – Research Unit Machine Elements and Transmissions for Aviation

Within Europe, a helicopter flight emergency occurs about once a week and a fatal accident about once a month. In order to prevent such emergencies and accidents, TU Wien is developing various technological improvements for rotorcraft. TU Wien fully supports the goals of the European Union Aviation Safety Agency (EASA): the EASA Rotorcraft Safety Roadmap was established in 2018. It has the goal of decreasing the number of helicopter accidents by half, by the year 2028.

Focus on the main gearbox

Between 2009 and 2016, just over the North Sea alone, about 50 people lost their lives in accidents caused by mechanical failure. The failures were caused by problems with the mechanical drivetrain, particularly in the main gearbox, which connects the turbines to the rotor. “The fault-free construction and function of the mechanical drivetrain is of the greatest importance— because with the help of auto-rotation, even in case the transmission completely fails, pilots can still land the helicopter safely,” explains Prof. Michael Weigand from the Institute of Engineering Design and Product Development.

At TU Wien, there are many safety-related research activities in the area of machine elements and transmissions for aviation. All work is oriented around following aviation regulations, especially the regulatory framework and Certification Specifications of EASA. The research teams' extensive know-how in this area stems from its contribution to the development of gearboxes and transmissions for the helicopter “Kamov Ka-62”, as well as from Prof. Weigand’s industry experience.

Independent Expertise on Safety

TU Wien contributes to the European aviation industry as an independent and unbiased research centre. These characteristics are especially important as regards safety.

Research on safety is being continually conducted— topics range from improving lubricants, to the smart monitoring of gear boxes, all the way to preventing loss of lubrication during flight. TU Wien has implemented a computer-aided version of the Failure Mode, Effects and Criticality Analysis (FMECA). It was validated using existing helicopter gearboxes as references. Validation testing provides the means for integrating the FMECA into the construction process. Also, as part of an EASA tender, TU Wien presented a comprehensive concept for the improvement of the safety of helicopter transmissions.

Tribology, the science of friction and mechanical wear, plays a main role in transmission improvement. At TU Wien, surfaces and lubricants are analyzed to a very precise degree, and innovative lubricant additives as well as solid lubricants are being developed. “From the point of view of tribology, a helicopter is especially interesting, because that is where we have to deal with extreme situations,” says Prof. Carsten Gachot from the Institute for construction science and product development.

“Transmissions should be able to cope with as much load as possible, and do that at very high temperatures,” says Prof. Carsten Gachot. Intense heat and load can lead to mechanical damage, and in the very worst case, a catastrophic failure of the transmission. This must be prevented.

Fluid Salts

Michael Weigand and Carsten Gachot are working together with Prof. Katharina Schröder, at the Institute of Applied Synthetic Chemistry at TU Wien, on a new type of lubricant additive at the. The work concerns salts which are fluid at room temperature— these are known as ionic fluids or ionic liquids. “The ions enter into a chemical bond with the metal surface,” explains Carsten Gachot. “In this way, a thin film forms on the surface which prevents contact between two metal parts of the machine, thereby minimizing friction.” As a next step, ionic fluids are being tested as additives, with a view of blending them with the currently approved oils for helicopter transmissions.

Like a Deck of Cards

Promising 2-D materials are also being investigated– these are solids that consist of extremely fine, thin layers of material, like the famous carbon material known as graphene. At TU Wien, a special class of these 2D materials will be investigated; it is known as “Mxene” or Maxene. 3 or 4 of these layers together are as thin as the hundredth of the width of a hair. “The way they work can easily be understood by looking at a deck of cards,” says Carsten Gachot. “It’s very difficult to tear a deck of stacked cards. However, the cards can easily glide along the direction of the card surface.” The layers glide so well that they drastically reduce the wear and tear on mechanical parts.

Additionally, investigations are being conducted at TU Wien to find out how laser technologies can alter the surfaces of machine elements in ways that reduce friction even further.

All of these developments will contribute to the improvement of helicopter safety in the near future. Come see for yourself at the European Rotors Exhibition from the 16th to the 18th of November in Cologne, Germany.

_______________________________

TU Wien is situated in Vienna, ranks among the top patent applicants, and is the largest technical university in Austria with 5,400 scientists and employees, and 26,000 students (one third from abroad).

TU Wien is Austria’s largest contractor of EU-research programs. The volume of projects which are raised from enterprises and competitive research funds amounts to close to 40% of the state's basic funding.

TU Wien offers innovations for aviation: from new concepts and designs to testing as well as support in production and certification. For manufacturers, suppliers, designers and service providers in the aviation industry, a number of innovative technologies, outstanding test and research services as well as support in certification are available.

At EUROPEAN ROTORS 2021 the Research Unit Machine Elements and Transmissions for Aviation at TU Wien presents:

- Improved Safety of Rotorcraft Drivetrains – assessment, testing, improvement, monitoring, and teaching

- Advanced lubricant additives and surfaces for high-performance applications – ionic fluids as oil additives and new 2D-materials for improved protection

- Innovative transmissions for aviation – new rotorcraft concepts, improvement of traditional gearboxes, safety of drivetrains

- Aviation at TU Wien – know-how and laboratories for: transmissions, new lubricants & tribology, aircraft systems & design

- New microsensor for electric field strengths – measure electric fields and voltage with a safe, mobile, robust and contactless device

- INMOX – smart detection of metal chips, and monitoring system fo gearboxes

_______________________________

Further Inquiry

Regarding scientific questions:

Prof. Dr.-Ing. Michael Weigand

TU Wien – Research Unit Machine Elements

and Transmissions for Aviation

www.ikp.tuwien.ac.at/mel, opens an external URL in a new window

+43 1 58801 30730

michael.weigand@tuwien.ac.at

Prof. Dr.-Ing. Carsten Gachot

TU Wien – Research Unit Tribology

www.ikp.tuwien.ac.at/tribologie, opens an external URL in a new window

+43 1 58801 30763

carsten.gachot@tuwien.ac.at

Sender:

Peter Heimerl

TU Wien – Research Marketing

www.tuwien.at/foma, opens an external URL in a new window

M: +43 664 605883320

T: +43 1 58801 406110

foma@tuwien.ac.at