The behavior of cells strongly depends on their environment. If they are to be researched an manipulated, it is crucial to embed them in suitable surroundings. Aleksandr Ovsianikov is developing a laser system, which allows living cells to be incorporated into intricate taylor-made structures, similar to biological tissue, in which cells are surrounded by the extracellular matrix. This technology is particularly important for artificially growing biotissue, for finding new drugs or for stem cell research. Ovsianikov has now been awarded the ERC Starting Grant from the European Research Council (ERC) of approximately 1.5 million Euros.

High-Tech-Structures for Biomedical Research

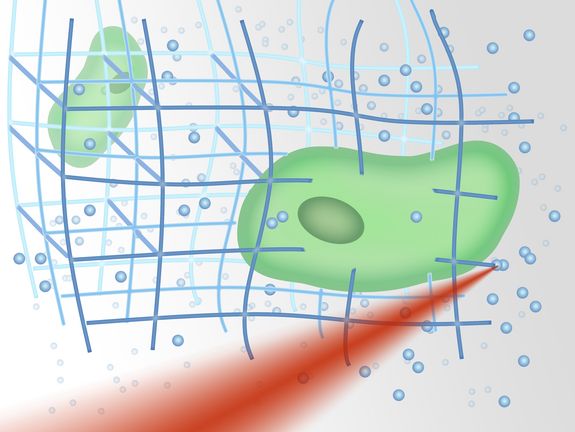

“Growing cells on a flat surface is easy, but such cell cultures often behave differently from the cells in a real three dimensional tissue”, says Aleksandr Ovsianikov. While in two dimensions, conventional Petri dishes are used, no standard system has yet been available for three dimensional cell cultures. Such a 3D-matrix needs to be porous, so that the cells can be supplied with all the necessary nutrients. Furthermore, it is important that the geometry, chemical and mechanical parameters of this matrix can be precisely adjusted in order to study and induce necessary cell responses. Also, it is important that the structure can be produced quickly and in large quantities, as biological experiments usually have to be carried out in many cell cultures at the same time to yield reliable data.

These requirements are met very well by the research group “Additive Manufacturing Technologies” at the Vienna University of Technology. The interdisciplinary team of researchers has been developing special technologies to create three dimensional structures with precision on a sub-micrometer scale. “We want to develop a universal method, which can serve as a standard for three dimensional cell cultures and which can be adapted for different kinds of tissue and different kinds of cells”, says Aleksandr Ovsianikov.

Laser Turns Liquid into Taylor-Made Scaffold

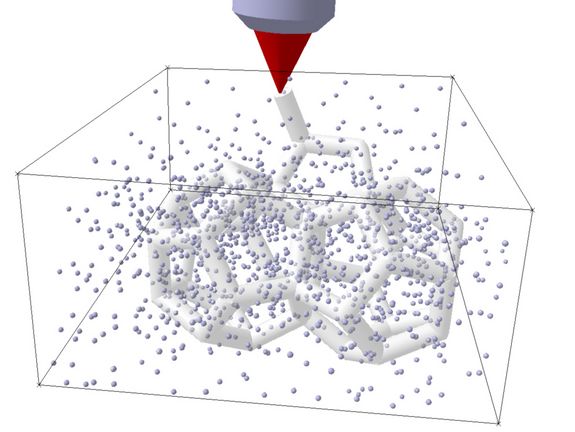

At first, the cells are suspended in a liquid, which mainly consists of water. Cell-friendly molecules are added, which react with light in a very special way: a focused laser beam breaks up double bonds at exactly the right places. A chemical chain reaction then causes the molecules to bond and create a polymer.

This reaction is only triggered when two laser photons are absorbed at the same time. Only within the focal point of the laser beam the density of photons is high enough for that. Material outside the focal point is not affected by the laser. “That is how we can define with unprecedented accuracy, at which points the molecules are supposed to bond and create a solid scaffold”, explains Ovsianikov.

Guiding the focus of the laser beam through the liquid, a solid structure is created, in which living cells are incorporated. The surplus molecules which are not polymerized are simply washed away afterwards. This way, a hydrogel structure can be built, similar to the extracellular matrix which surrounds our own cells in living tissue. Ideas from nature are imitated in the lab and used for technological applications. This approach, called ‘bio-mimetics’ plays an increasingly important role, especially in materials science. Aleksandr Ovsianikov is confident that in many cases, this technology will render animal testing unnecessary and yield much quicker and more significant results.

Turning Stem Cells into Tissue

Stem cell research is a particularly interesting field of application for the new technology. “It is known that stem cells can turn into different kinds of tissue, depending on their environment”, says Aleksandr Ovsianikov. “On top of a hard surface, they tend to develop into bone cells, on a soft substrate they may turn into neurons.” In the laser-generated 3D structure the rigidity of the substrate can be tuned so that different types of tissue can be created.

Lithuania, Germany, Austria

Interdisciplinary cooperation is crucial for this project, which connects engineering, material science, biology and chemistry. The possibility to work with experts in such a wide range of scientific fields at one single research facility was an important reason for Aleksandr Ovsianikov to come and work at the Vienna University of Technology. Born in Lithuania, Ovsianikov obtained his PhD in Hannover, Germany. Now he has been working at the Vienna University of Technology for two years.

Aleksandr Ovsianikov’s project has now been awarded an ERC Starting Grant from the European Research Council. These grants aim to support up-and-coming researchers who have the proven potential of becoming independent research leaders. Within the next five years, Ovsianikov has the opportunity to establish his own research team and continue his quest to bring together materials science, physics and cell biology.

Contact

Dr. Aleksandr Ovsianikov

Institute of Materials Science and Technology

TU Wien

Favoritenstr. 9-11, 1040 Vienna

Phone: +43 1 58801 30830

Email: aleksandr.ovsianikov@tuwien.ac.at

Sender

Dr. Florian Aigner

Service Unit of PR and Marketing

TU Wien

Operngasse 11, 1040 Vienna

Phone: +43 1 58801 41027

Email: florian.aigner@tuwien.ac.at