Every bone is unique. If you need a bone substitute after an accident, it is important that its shape is adapted precisely to your body. This sounds like the perfect job for 3D printing. These days 3D printing is often the tool of choice when, rather than mass producing a series of identical objects, there is a need to fabricate individual items customised to fit perfectly.

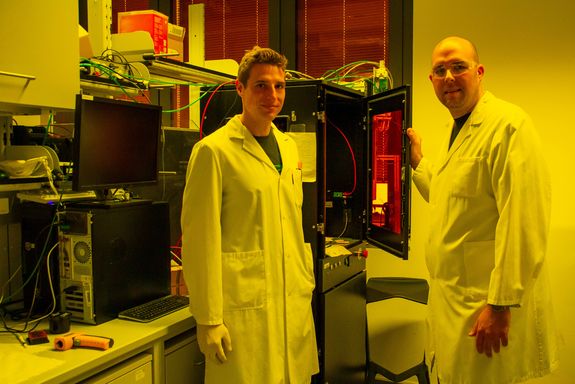

However, it is difficult to find suitable materials to construct bones out of that can be processed by a 3D printer. At TU Wien, they are seeking to redesign and improve these materials. Research in this area will take place in a new Christian Doppler Laboratory (CD Laboratory "Advanced Polymers for Biomaterials and 3D Printing"), which was unveiled on 25 June 2019. The new laboratory is being financed by the Federal Ministry for Digital and Economic Affairs (BMDW) and corporate partners KLS Martin, Lithoz and TCC.

"Using 3D printers in medicine will unlock new potential both for individuals and the economy. Innovative medicine, such as customised bone implants, opens up exciting possibilities and growth prospects for those in this industry," stresses Elisabeth Udolf-Strobl, Minister for Digital and Economic Affairs.

Living material

"A bone should not be viewed as an inflexible, inanimate object," explains Stefan Baudis from the Institute of Applied Synthetic Chemistry at TU Wien, who is heading up the new CD Laboratory. "The bones in our body are continuously being broken down by certain cells in the body, and built up again by other cells at the same time. That's why broken bones can heal themselves of their own accord." These cells are supplied by their own blood vessels, which permeate the bones and aid transport of the required substances.

All the body needs is a suitable supporting scaffold. This will then be colonised by the body's own cells and transformed into a completely normal bone. "Our aim is to use 3D printing technology to produce such a supporting scaffold," continues Baudis. A damaged bone fragment can be precisely measured using modern imaging techniques. You would then be able to select the required bone segment on the computer, and the 3D printer would produce a bone scaffold of precisely the right shape, one layer at a time, all within a matter of hours. This would then be glued to the natural bone during an operation.

The complex requirements of the bone scaffold

From a materials-science perspective, this poses a major challenge, since the artificially produced bone scaffold needs to fulfil a whole range of requirements: it needs to have a porous structure so that it can be penetrated by the body's bone-building cells and to enable substances to be transported. It needs to be solid but not too brittle to prevent it breaking straightaway. It must be possible for the body to break it down within a reasonable period of time, so that when it has been replaced by natural bone, none of the structure remains. Moreover, calcium phosphate particles should be embedded into it, which will then be converted into the bone material.

At the same time, the material must be suitable for 3D printing: it should initially remain fluid at room temperature until light of the right wavelength is shined onto it. Doing so would then trigger a chemical chain reaction to harden the material at the precise points where the light hits it.

"We already know a lot about the chemistry of the individual components required for this process," explains Baudis. "Now we are focusing our research on finding the right mixture of materials so that all these requirements are met."

There will also be a need to further develop the 3D printing process itself. TU Wien already has extensive experience in developing new 3D printing technologies; the research project is drawing on the expertise of all sorts of other research groups at TU Wien.

About Christian Doppler Laboratories

At Christian Doppler Laboratories, application-orientated basic research is undertaken at a high level, with outstanding scientists cooperating with innovative companies to this end. In promoting such collaboration, the Christian Doppler Research Association provides an example of best practice internationally.

Christian Doppler Laboratories are jointly financed from public funds and by participating companies. The most important public funding body is the Federal Ministry for Digital and Economic Affairs (BMDW).

Contact:

Dr. Stefan Baudis

Institute for Applied Synthetic Chemistry

TU Wien

T: +43-1-58801-163730

stefan.baudis@tuwien.ac.at