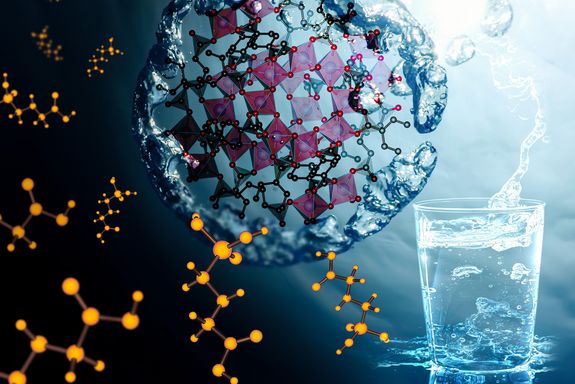

MOFs are built like molecular scaffolds implementing the principles of reticular chemistry: metallic nodes are linked together by organic molecules to form rigid, repeating frameworks filled with tiny, uniform pores. This modular “Lego-like” chemistry allows scientists to create structures with precise functions – and more than 120 000 different MOFs have already been synthesized worldwide. The idea is simple yet revolutionary: by choosing different metals and linkers, researchers can tune a material’s internal geometry, chemistry and reactivity almost at will.

What makes these materials so extraordinary is their immense internal surface area – in some cases over 7 000 square metres per gram. In a handful of powder, every atom sits at or near a surface, ready to interact with its surroundings. This challenges the traditional view of solids as dense, inert blocks of matter. In MOFs, everything is interface. They unite the extended, continuous nature of a solid with the tunability of molecules, merging electronic bands and discrete molecular states into one versatile platform.

This combination of order and openness has unleashed an explosion of applications. MOFs can store and separate gases such as hydrogen, methane and CO₂ with unprecedented efficiency, and are front-runners in direct air capture technologies. Their enormous surface area and chemical flexibility make them ideal for purifying air and water, removing pollutants and volatile organic compounds. In medicine, they serve as carriers for drug delivery, protecting sensitive molecules and releasing them on demand. And in the energy sector, their ability to coordinate metals and organic ligands at the atomic scale has opened exciting pathways for photo- and electrocatalysis – driving hydrogen generation, CO₂ conversion and ammonia synthesis while efficiently separating and extracting charges.

At TU Wien, the Molecular Materials and Catalysis (MMC) group led by Prof. Dominik Eder has become an important hub for MOF research in Europe, working closely with some of the world's greatest experts in the community, including Prof. Kitagawa. Their focus lies on photocatalytic and electrocatalytic processes – using light and/or electrons to split water, capture carbon and synthesize ammonia, purification technologies to remove pollutants in water and air – as well as the integration of MOFs into biosensors and air-capture systems.

At TU Wien, the group collaborates with Prof. Katharina Schröder on CO₂ conversion, Prof. Carsten Gachot on lubrication, Prof. Günther Rupprechter on surface science of MOF thin films, and Prof. Florian Libisch on computational design, together exploring how these frameworks can drive energy conversion, purification and sensing technologies. The group also plays a key role in Austria’s Cluster of Excellence MECS, which unites fundamental and applied research in materials for energy conversion and storage.

Despite the progress, key scientific challenges remain. Researchers are now learning to engineer defects and ligands with atomic precision to optimize performance, and to introduce single-atom catalytic sites that combine high activity with stability. At TU Wien, the newly developed SELIRE process allows the selective integration of such active sites while carving mesoporous “highways” through the framework to overcome diffusion barriers. The team has also created several new MOFs – from TUW-1 to TUW-11 – designed for durability and catalytic versatility.

The vision for the future is equally ambitious. TU Wien aims to use MOFs as both model systems and functional materials, linking theory, synthesis and device development. Together with colleagues at TU Graz and the University of Vienna, the university hopes to establish an Austrian MOF Network to consolidate national expertise and accelerate industrial translation in areas such as carbon capture, environmental purification and sustainable fuels.

The Nobel Committee today called MOFs a “new class of materials that expands the boundaries of chemistry.” For researchers at TU Wien, it is also a confirmation that the field’s most imaginative ideas – porous crystals that act like molecular machines – are no longer a dream. They are already shaping the technologies of tomorrow.

Contact:

Prof. Dominik Eder

Head of Division Molecular Materials Chemistry (MMC)

Institute of Materials Chemistry, TU Wien

www.tuwien.at/tch/mmc