For many industrial applications one needs synthesis gas, also known as “Syngas”, a mixture of hydrogen (H2) and carbon monoxiode (CO). In addition to the established production method via steam reforming, synthesis gas can alternatively—and even more energy‑efficiently—be produced from methane (CH₄) and oxygen. However, in this process the total oxidation (combustion) of methane to CO2 and H2O must be avoided, which is why there is vivid research on syngas production worldwide.

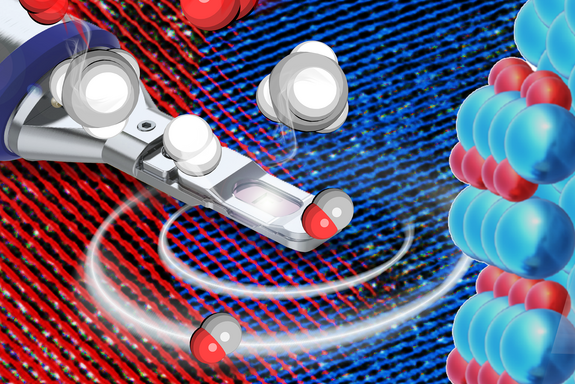

Catalysts containing elements such as palladium are used for this purpose. Until now, however, it has been unclear exactly how the conversion of methane to syngas proceeds on palladium surfaces. Through a collaboration between TU Wien and the National University of Singapore (NUS), it has now been possible to observe the process using high‑resolution transmission electron microscopy —by so‑called operando TEM— combined with computational simulations. The results show that the reaction requires a synergy between different catalyst regions.

Palladium and palladium-oxide

“Methane is the main component of natural gas. Today we do not only use it for heating—which is problematic for reasons of global warming—but also as a feedstock for producing chemicals and fuels,” says Prof. Günther Rupprechter from the Institute of Materials Chemistry at TU Wien. “Even in the future, methane will therefore play a role in generating syngas and probably cannot be completely replaced within the next decade.”

This is why intensive research is being carried out today to find new processes to produce syngas from methane more efficiently while avoiding over‑oxidation—that is, combustion to CO₂ and water. This process is called “partial oxidation of methane” (POM). “In recent years we have investigated POM on various catalysts, most of which were nickel‑based,” Rupprechter says.

A microreactor in an electron microscope

It was already known that catalysts made of metal nanoparticles work well. But the open question was what exactly happens to the individual metal nanoparticles during the catalytic reaction. “In particular, we wanted to know: if the reaction is carried out with palladium nanoparticles, is palladium itself responsible for the catalysis, or palladium oxide, which forms during the reaction?”

This question could now be addressed for the first time through a combination of advanced approaches: The team observed the nanoparticles in real time during the catalytic reaction using high‑resolution transmission electron microscopy. At the same time, mass spectrometry was used to monitor which products form at which point in time—and all of this was complemented by computer simulations. This combination made it possible, for the first time, to obtain a more precise mechanistic picture of the process.

How does the catalyst work ?

Alexander Genest from the TU Wien team, who was previously affiliated to the A*STAR High Performance Computing Centre in Singapore, has kept the collaboration between TU Wien and Singapore alive over the years. “Using computational modeling, we had previously looked into Pd nanoparticle oxidation and CO oxidation, so that the extension to methane oxidation was a very promising target”, says Alexander Genest.

Together with PhD candidate Parinya (Lewis) Tangpakonsab, he carried out simulations based on density functional theory (DFT) to study methane activation and the subsequent reaction steps. “We wanted to understand the origin of partial and total oxidation and to clarify exactly what happens at the atomic level,” says Tangpakonsab.