The development of combustion processes for conventional reciprocating engines and special engines, including adaptation to a wide range of fuels, is a traditional focus of the institute. Starting from the charge motion with turbocharging via mixture formation and ignition up to combustion, all areas are covered. The following are some of the current research activities:

Sustainable fuels for aviation

In order to achieve climate neutrality in aviation, the main focus is on the introduction of alternative energy sources in addition to process efficiency improvements and the use of new technologies.

Sustainable Aviation Fuels (SAFs) are made from non-fossil raw materials that have an energy density required for aviation. Depending on the manufacturing process, they can be blended with conventional kerosene at a blending rate of up to 50 (vol.) %. Due to deviating chemical and physical properties compared to kerosene, the mixture preparation and engine combustion must be adapted. The necessary research work is being carried out at the Institute of Powertrains and Automotive Technology (IFA) at the Vienna University of Technology on an aircraft engine with cylinder pressure-based control of the combustion process.

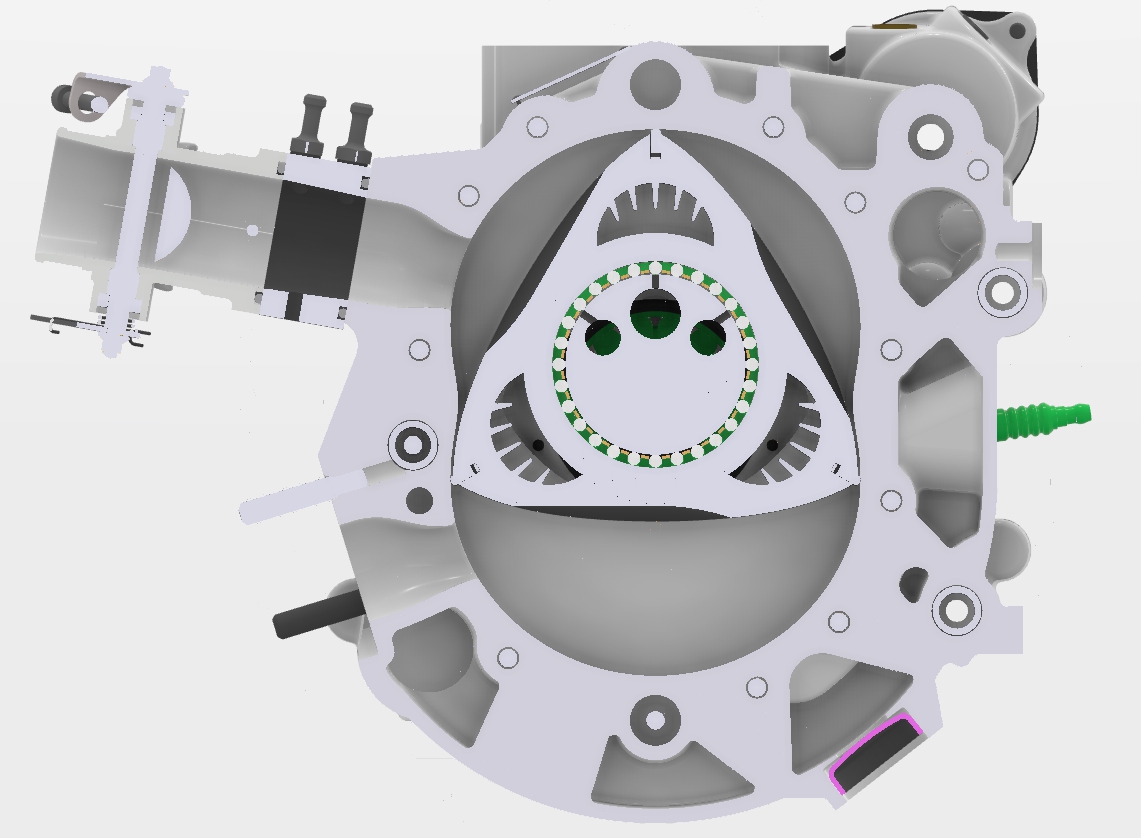

One area of application for such fuels is the Wankel engine, named after its inventor. Due to its smooth running as well as its high power-to-weight ratio, this engine is of particular interest for aviation applications. The IFA is conducting special research on the development and optimization of new combustion processes that allow the use of renewable fuels. The interaction of experimental and numerical investigations enables a better understanding of the gas exchange, the mixture preparation as well as the turbulent combustion. The goal is the realization of reliable engine operation with sustainable fuels under all boundary conditions, especially the low temperature range relevant in aviation.

Innovative ignition processes

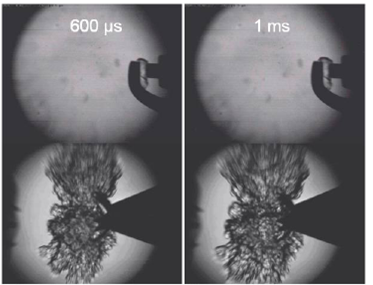

The IFA at the Vienna University of Technology has many years of experience and expertise in the field of alternative ignition systems (here especially in laser ignition, corona ignition, high-frequency AC ignition). Investigations of ignition behavior in a combustion chamber showed the potential of the multiple spark ignition system and large-volume, rapid ignition with the corona ignition system.

CO2 savings by means of numerical combustion process development

The modeling of the combustion process enables a deep understanding of the processes in the combustion chamber and thus the identification of optimization potentials. Depending on the optimization goal at hand, suitable numerical models are developed at the IFA.

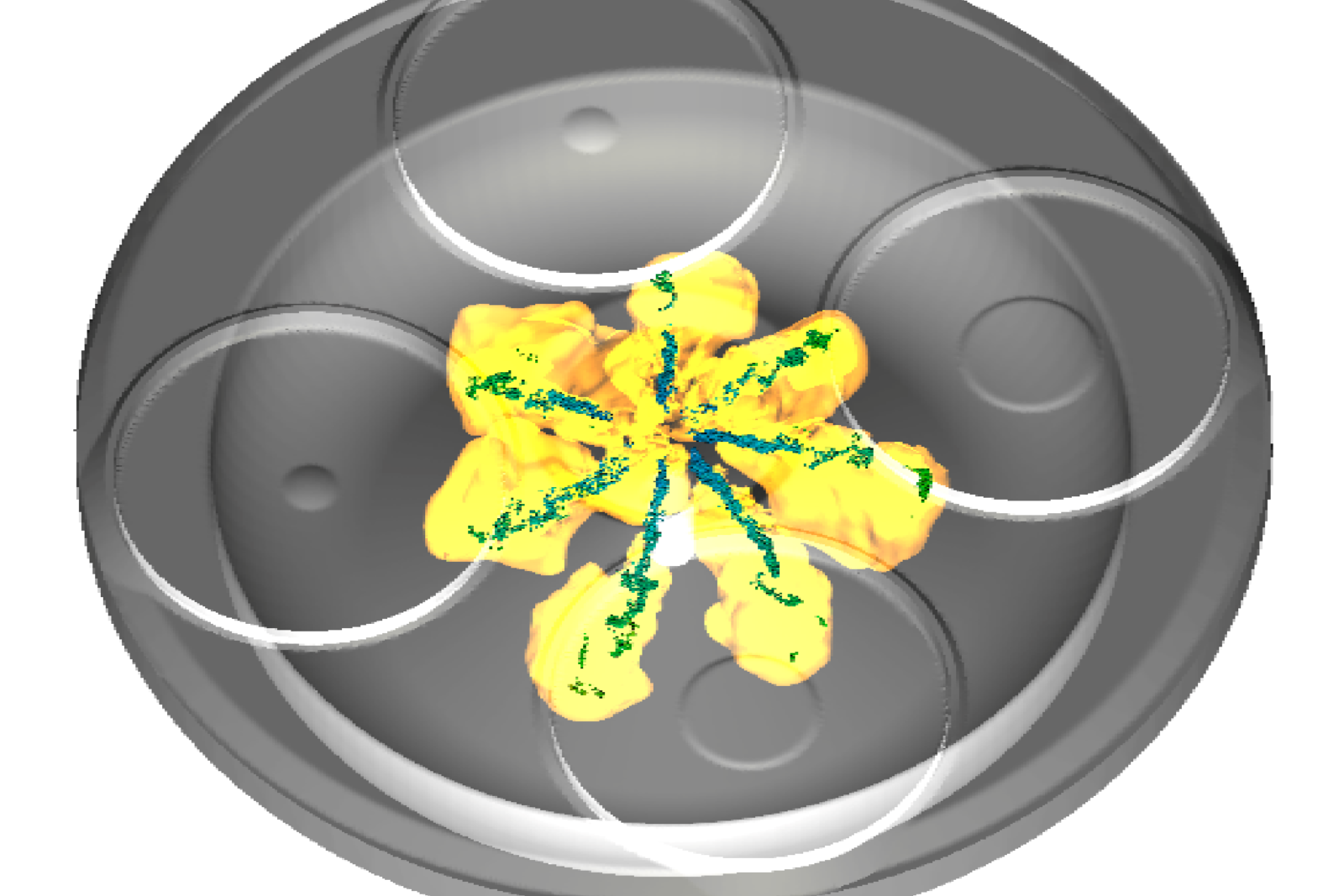

With regard to CO2-neutral mobility, combustion processes with regenerative fuels are coming to the fore. In the field of non-premixed diesel engine combustion, fuels containing oxygen, such as polyoxymethylene dimethyl ether (PODE or OME), are being discussed. These fuels make it possible to lower the soot level beyond the known soot-NOx trade-off and have great potential for implementing zero-emission mobility.

Numerical investigations using CFD simulation provide detailed insight into the break-up of the spray, the formation of the vapor phase and the reaction kinetic processes leading to ignition. A combination with optical investigations on suitable chambers and engines allows a detailed understanding of the inner-engine processes. This enables specific process optimization for oxygenated sustainable fuels.

An alternative way to reduce pollutant emissions is the special case of dual-fuel combustion. In this technology, which is used primarily in large engines, a lean fuel gas/air mixture is ignited by a diesel pilot. This significantly reduces climate-damaging CO2 emissions as well as nitrogen oxide and soot emissions.

The mixing and ignition of two fuels, as well as the turbulent flame progressing from the ignition jet into the lean fuel gas, represent a major challenge in terms of model technology and are the subject of research.

The fuel-efficient operation of the gasoline engine is limited by irregular combustion. In addition to engine knocking, pre-ignition poses a significant damage potential in highly charged engines. Numerical and experimental in-situ investigations using high-speed camera and fiber optics have been carried out at the institute in recent years to investigate the causes of these uncontrolled ignition events. Recent investigations as part of a European research project identified reactive deposits as likely triggers of pre-ignition events. A fuel model for predicting wall film formation in the combustion chamber, as well as a particle ignition model including detailed reaction kinetics, were developed and provided by the institute, enabling the identification of pre-ignition critical operating points.

Contacts:

Assoc.Prof. Dr. Peter Hofmann

Phone: +43 1 58801 31576

peter.hofmann@ifa.tuwien.ac.at

Assoc.Prof. Dr. Thomas Lauer

Phone: +43 1 58801 31575