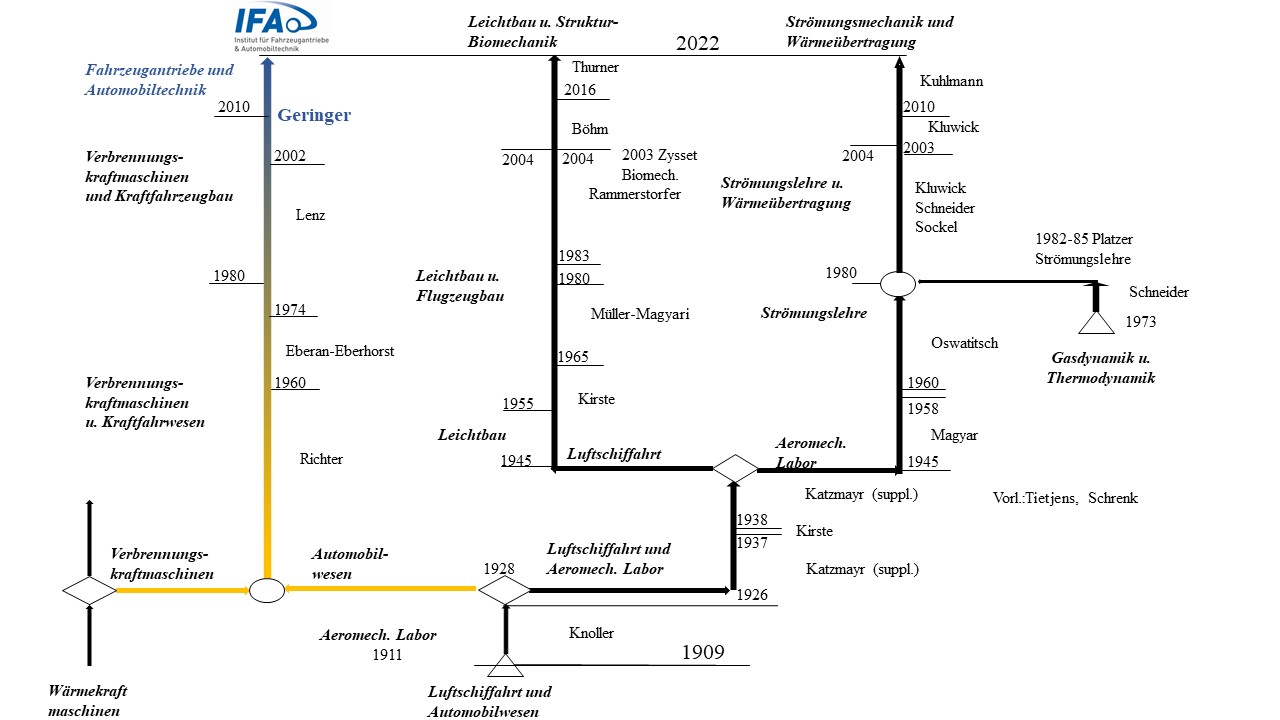

The historical beginning of the renowned institute goes back to the beginning of the 20th century: As early as 1904, Professor Baudiss had read about reciprocating internal combustion engines (gasoline and diesel engines) at the “Technische Hochschule in Wien”, at that time still in connection with piston steam engines. Powerful piston engines were essential for the emerging aviation development and thus the coupling of automotive engineering with aeromechanics and aviation as a joint institute. It was not until 1928 that the institute was separated into two independent institutes.

The original Chair of Internal Combustion Engines and Automotive Engineering was headed by Prof. Richter through World War II, followed in 1963 by Prof. Eberan-Eberhorst (until 1974) and Prof. Lenz (until 2002). The name of the institute was adapted to the rapid development of drives at the beginning of 2010: “Institute for Combustion Engines and Automotive Engineering” became “Institute for Vehicle Drives and Automotive Engineering”.

In the period between the two world wars, the development of the internal combustion engine into the light engine took off, not least thanks to the help provided to the designer and engine builder by scientific research. Until then, pure empiricism had dominated the field. In all means of motorized transport on land, on water and in the air, the internal combustion engine began an unimagined triumphal procession – over all other types of propulsion.

However, the widespread use of the internal combustion engine in particular also revealed the emerging problems of individual mobility, especially in large cities with basin locations such as Los Angeles: in addition to performance and high efficiency, the overriding research topic of minimizing pollutants was added. In the 1970s, this research content took up the bulk of the institute’s work and continues to this day – with catalytic converter technology, particulate filters and nitrogen oxide aftertreatment. Under the leadership of Prof. Lenz, the institute was at the forefront of the new exhaust gas legislation in Austria and Europe.

This also required state-of-the-art measurement equipment: as early as 1962, a dynamic 4-drum rolling test bench was installed for vehicle measurements and later for the important emission tests. The number of engine test benches was increased, but they were also expanded, especially for pollutant measurements.

As early as the late 1970s – triggered by the so-called “oil crisis” – energy supply also became increasingly important: fuels from domestic production such as vegetable oils and biodiesel gained increasing importance in research. One of the first used cooking oil tractors was developed at the Institute in the 1980s.

Of particular importance was also a method developed at the institute for recurrent vehicle inspection with simple function control of the 3-way catalytic converter system. Prof. Pucher developed such a method, which is still used as standard in workshops.

Since the beginning of this millennium, the call for alternative drive systems – from hybrid to purely electric drives and the fuel cell – has been essential.

When Prof. Geringer took over the management of the institute in 2002, this branch of research became the largest in the institute. Prof. Hofmann has had a significant impact on hybrid drives, both in research in numerous funding programs and in teaching and with specialist books. From the former primarily experimental research, method development and experimental validation under Prof. Lauer have become a major additional pillar.

With the move to the new and most modern equipped laboratory in the Franz-Grillstraße at the Arsenal in 2019, it allows the institute to further research and improve all kinds of propulsion systems – whether stationary for power generators, mobile for vehicles or ships up to aircraft with piston or Wankel engines. This is accompanied by the possibility of using all known forms of energy for such forms of propulsion: whether classic fossil hydrocarbons, via synthetic fuels, biofuels or hydrogen and electrical energy.

12 fully developed four-quadrant E-machines for aggregate testing with state-of-the-art conditioning and measurement equipment enable propulsion engine/generator and powertrain research.

The new four-wheel chassis dynamometer with high-power current charging point enables ALL kinds of vehicle propulsion, emission and comfort measurements from -30°C to +50°C and up to 180 km/h driving speed of any driving conditions and profiles.

But the most important potential are the people behind it: About 35 scientists and another good 20 system-maintaining specialists make up the team of the IFA – the Institute of Vehicle Drivetrains and Automotive Engineering.