As early as the 1980s, the institute was involved in the development and introduction of the 3-way catalytic converter in Austria. Since then, exhaust gas aftertreatment has been a central R&D focus at the IFA, as shown by some current research work:

Selective Catalytic Reduction (SCR)

In order to comply with future international emissions standards, further reductions in nitrogen oxide emissions are necessary. A promising approach for medium-sized and large passenger cars, as well as trucks, is the so-called SCR technology (Selective Catalytic Reduction).

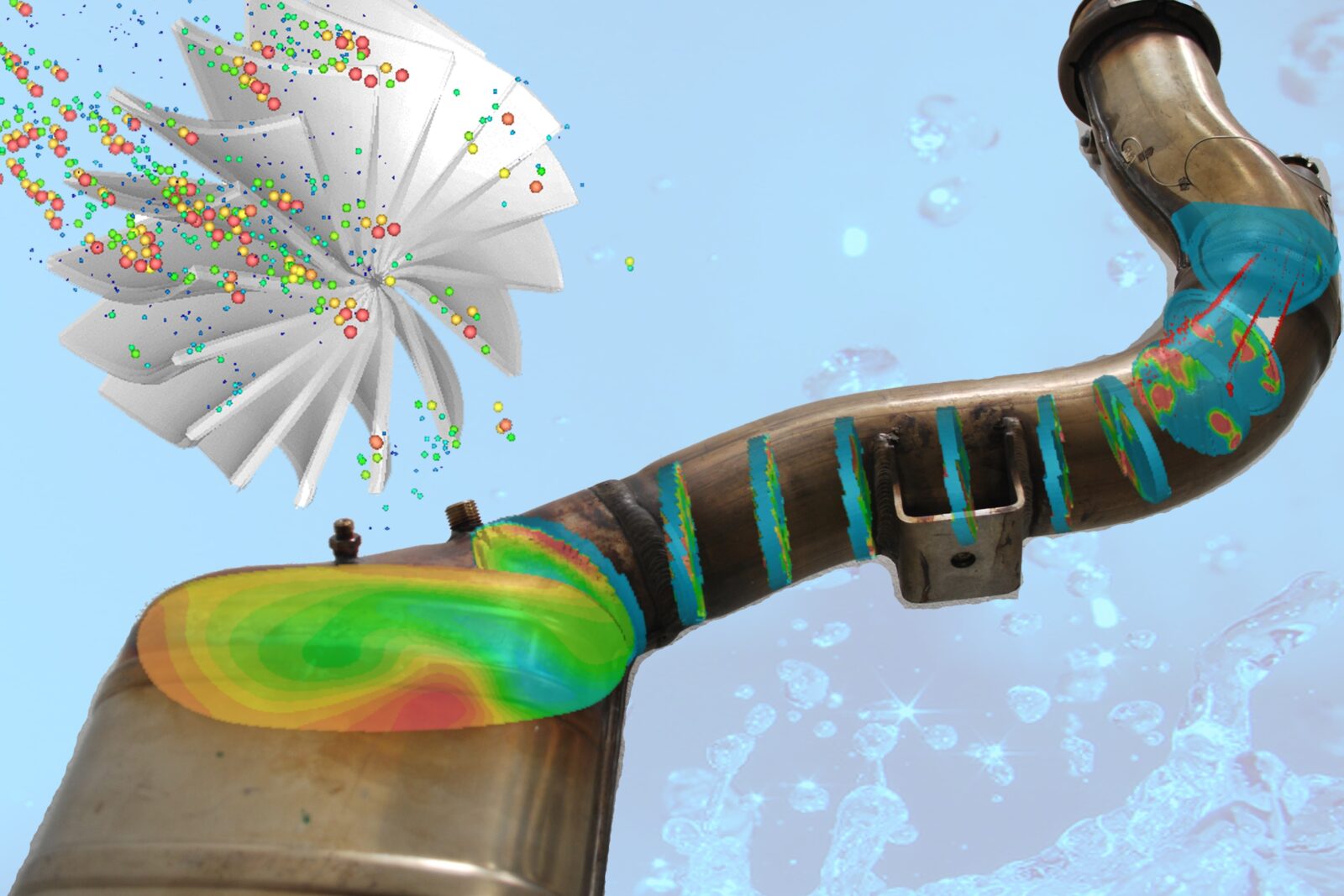

The system is based on the injection of a urea-water solution into the exhaust system. Ammonia is gained from the fine spray in the hot exhaust gas. This is then used in an SCR catalytic converter to reduce the harmful nitrogen oxides. For effective neutralization of the nitrogen oxides, it is important that the ammonia is released and mixed quickly to enable the best possible use of the catalyst and to avoid solid deposits in the mixing section.

At the Institute for Powertrains and Automotive Technology at the TU Wien, research into development and design of SCR systems has been carried out for many years. Together with international partners, a comprehensive modeling approach was developed to represent the injection, the complex behavior of the droplets on the hot walls of the exhaust system up to the formation of solid deposits from liquid wall film. Experimental methods such as IR thermography, high-speed imaging, FT-IR and Wilhelmy Plate Methode were used.

Particulate Matter

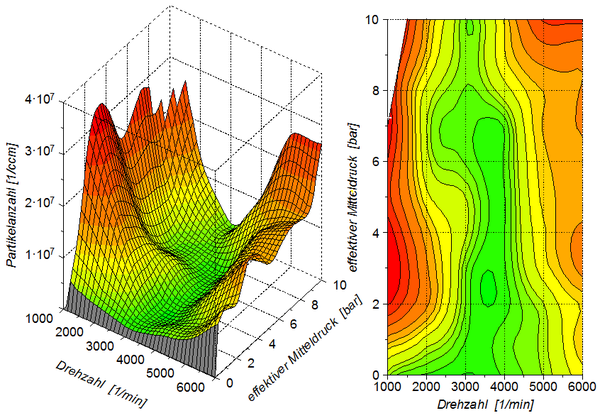

Particulate matter is formed during low-oxygen combustion and from the combustion of lubricating oil. The resulting particle emission is typically recorded as particle mass PM – deposited on a filter blade – or in terms of particle number PN – using a particle counter. PM is determined by differential weighing of the filter blade before and after loading with exhaust gas. For particle counting, condensation particle counters are mainly used in stationary laboratory applications.

At our institute, research work is being carried out on particle reduction in a small engine. In order to clarify the cause of generation, the particle mass and number as well as the particle size distribution are measured in a conditioned dilution tunnel. With the help of the number size distribution, the particle mass can be inferred via adequately assumed particle volume and expected density. Thus, the limited particle indices PN and PM can be evaluated.

Contacts:

Univ.Prof. Dr. Bernhard Geringer

Phone: +43 1 58801 31500

bernhard.geringer@ifa.tuwien.ac.at

Assoc.Prof. Dr. Thomas Lauer

Phone: +43 1 58801 31575

thomas.lauer@ifa.tuwien.ac.at