From side stream to binder

In our latest paper in Green Chemistry (Royal Society of Chemistry), we demonstrate that unmodified technical lignins, a byproduct of pulping, can replace synthetic resins as the binder in all-wood composites. The process is straightforward: dissolve lignin in ethanol, impregnate holocellulose-fiber sheets, then hot-press. Across many lignin sources and processes, organosolv lignins most often delivered the highest strengths.

What we evaluated and learned

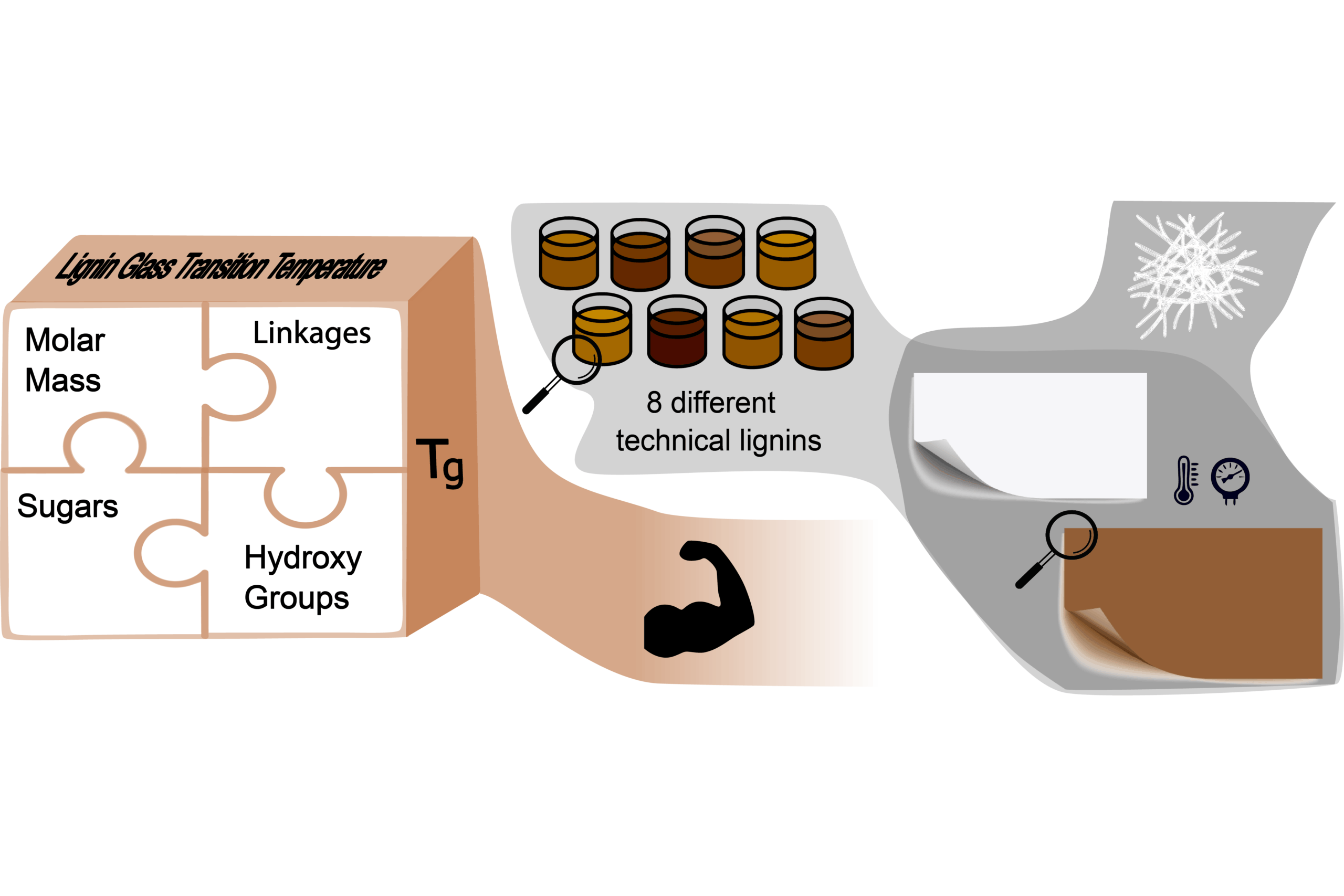

We combined mechanical testing with thermal, surface, and chemical analysis over a broad set of lignins. A key insight emerged: no single parameter predicts performance. Strength correlates with the combined effect of glass-transition temperature, native linkage types, hydroxyl group content, and polysaccharide impurities, features that govern how well lignin spreads through the fiber network and transfers load during hot pressing.

Why this matters

Within the examined operating window, we identified conditions that preserve hemicellulose and deliver well-disintegrated, single fibers. The resulting sheets show marked gains in inter-fiber bonding after hot-pressing, underscoring the role of hemicellulose in network formation. Compared with more severe treatments, the practical setting we recommend balances fiber integrity, yield, and performance, a compelling pathway for valorizing sawmill by-products with modest process requirements.

Why this matters for wood-based materials

Using lignin as the binder enables resin-free, wood-only composites made from widely available industrial streams. The multi-parameter guideline provides a practical basis for selecting lignins at scale and for designing reliable manufacturing routes for next-generation wood-based materials.

📄 Read the paper: Unmodified technical lignins as sustainable binders in structural biocomposites, Green Chemistry (2025), DOI: 10.1039/d5gc04157k.

🔗 Link: https://doi.org/10.1039/D5GC04157K

WoodComp3D

WoodComp3D